▼ Summary

High speed automatic bottle blowing machine has the advantages of high production, intelligent manufacturing and energy saving.

▼ Features Of Equipment

1. Higher Production Capacity, Smaller Machine.

Fully electric models for high-speed and stable operation, precise positioning, bottom mold connection for precise control of preform forming.

2. More Intelligent And Efficient Production Equipment.

This automatic smart production equipment can reduce manual operations to a minimum, while its smart designs ensure uninterrupted and more efficient production at the same time, including multiple security devices to ensure smooth preform infeed for continuous production without interruption, and efficient transfer system, heating system for lower energy consumption and pollution.

3. Heating System with Higher Efficiency.

The enhanced high-power heating lamp has a 20% increased heating efficiency, and is equipped with cooling devices to prevent neck deformation.

4. Easy Maintenance Structure.

Spindle system adopts right-side up heating, which provides less moving parts comparing to flip-type design. This gives less chance for component failure and machine down time.

5. Lower Production Costs.

The upgraded air recovery system can save up to 50% gas consumption as compared to previous generation models. When combined with the upgraded heating efficiency, the electricity consumption of the machines is greatly reduced by 30%, significantly lowering production costs.

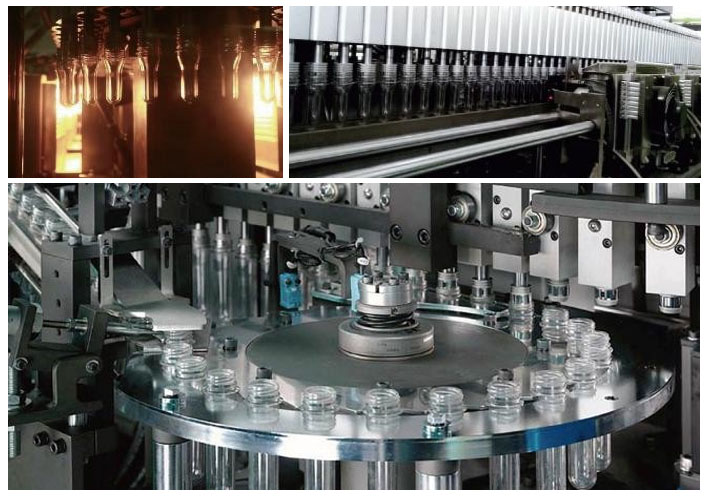

▼ Equipment Pictures

▼ Technical Specification

| Model | Unit | TIE-H6C | TIE-H8C | |

Molding | Clamping force | kg | 60000 | 72000 |

Clamping stroke | mm | 130 | 130 | |

Stretching stroke | mm | 320 | 350 | |

Bottom stroke | mm | 50 | 50 | |

Cavity pitch | mm | 120 | 120 | |

Number of cavity | 6 | 8 | ||

Container | Max container volume | ltr | 1.6 | 1.6 |

Neck diameter range | mm | 40 | 30 | |

Max container diameter | mm | 95 | 105 | |

Max container height | mm | 320 | 320 | |

Carriage unit | pcs | 126 | 162 | |

Theoretical Output | bph | 9000 | 18000 | |

Electrical System | Total power | kW | 48 | 78 |

Heating power | kW | 43 | 70 | |

Max.heating power | kW | 108 | 108 | |

Air System | Operating pressure | kg/c㎡ | 7 | 7 |

Air consuming | ltr/min | 1000 | 1000 | |

Blowing pressure | kg/c㎡ | 35 | 35 | |

Air consuming | ltr/min | 8000 | 9100 | |

Chiled Water | Operation pressure | kg/c㎡ | 4 | 4 |

Temperature | ℃ | 10-12 | 10-12 | |

Consuming | kcal/hr | 12000 | 37875 | |

Flow rate | ltr/min | 60 | 160 | |

Cooling Water | Operation pressure | kg/c㎡ | 2-4 | 2-4 |

Temperature | ℃ | 30 | 30 | |

Consuming | kcal/hr | 54000 | 104000 | |

Flow rate | ltr/min | 150 | 347 | |

Machine | Machine size(W*D*H) | mm | 6100*1900*2600 | 6600*1900*2600 |

Machine weight | kg | 6500 | 10000 | |

Current

Current